CL-100

| Max. swing | Ø420 mm |

| Swing over cross slide | Ø420 mm |

| Standard turning diameter | Ø350 mm |

| Max. turning length | 200 mm (gang-type / V8) |

| Travel of X-axis | 480 mm (V8) 240 mm (V8+ polygon cutting) |

| Travel of Z-axis | 400 mm |

| Spindle speed | 80~4000 r.p.m. |

| Spindle nose | A2-5 |

| Spindle bore | Ø55 mm |

| Bar capacity | Ø45 mm |

| Type | gang-type / V8 / polygon cutting ( opt.) |

| O.D. tool shank | Ø20 mm, Ø16 mm (polygon cutting) |

| I.D. tool shank | Ø25 mm |

| Spindle motor (15 min./cont.) | βiI8 (14.7 HP /10 HP) |

| Servo motor | X: βiS 8 (1.6 HP) / Z: βiS 8 (1.6 HP) |

| Hydraulic unit motor | 1 HP |

| Coolant pump motor | 1/2 HP |

| Height of machine | 2070 mm |

| Length of machine | 1800 mm |

| Width of machine | 2015 mm |

| Weight of machine | 2300 kg |

- Specifications are subject to change without notice.

Standard Equipment & Accessories

- FANUC 0i TF controller

- Main motor

- Hydraulic system

- 6” hollow 3-jaw hydraulic chuck

- Hard jaws & soft jaw 1 set/each

- Coolant tank & coolant system

- Moving door & splash guard

- Work light

- Single tool holder 4 pcs

- Double tool holder 1 pc

- Drill holder 1 pc

- Boring bar socket 1 set

- Drill socket 1 set

Optional Equipment & Accessories

- Subplate

- Chip conveyor & chip bucket

- Transformer

- V8 hydraulic turret

- V8 live turring turret

- Polygon cutting device

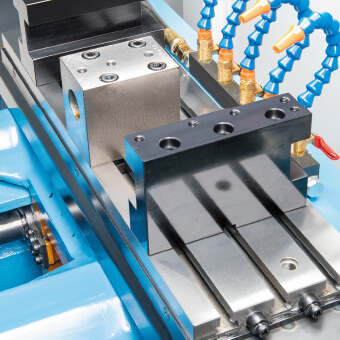

- The gang type table features shorter tools change time. When comparing with general NC lathe, it can save considerable time in tool returning, changing and feeding.

- For small-volume, large-variety production, common tool holders are applied. In case workpiece is varied, simply to change programs. Comparing with single-purpose machine or an automatic lathe, it can help reduce tools change time.

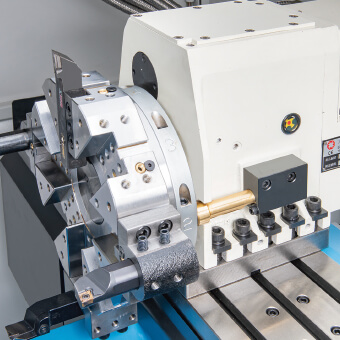

- The spindle installs with high precision P class angular contact ball bearings, providing outstanding axial and radial loading capacity and extreme machining stability.

- Max. spindle speed:

4000 r.p.m. (CL-10 / CL-100)

3000 r.p.m. (CL-12 / CL-120)

- 8-position hydraulic turret.

- Bi-direction, random tools selection and fast tool change.

- Suitable for cutting polygon on a round bar.

- The turret is used together with the polygon turning softwave.

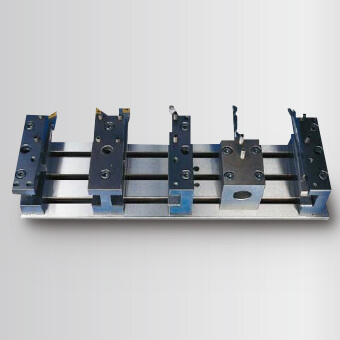

- The specially designed subplate can be changed entirely. For long-term machining and mass production, the operator may mount all tools on the subplate.

- In case of machining for different workpieces, simply remove the subplate without need to change tools one by one. This saves considerable time in tool setup.

- Ø32 mm ball screw is pretensioned to upgrade positioning accuracy.

- The ball screw is protected by a pipe to prevent pollution by chips and cutting coolant.

- Increasing the service life of ball screw.

| Max. swing | Ø420 mm |

| Swing over cross slide | Ø420 mm |

| Standard turning diameter | Ø350 mm |

| Max. turning length | 200 mm (gang-type / V8) |

| Travel of X-axis | 480 mm (V8) 240 mm (V8+ polygon cutting) |

| Travel of Z-axis | 400 mm |

| Spindle speed | 80~4000 r.p.m. |

| Spindle nose | A2-5 |

| Spindle bore | Ø55 mm |

| Bar capacity | Ø45 mm |

| Type | gang-type / V8 / polygon cutting ( opt.) |

| O.D. tool shank | Ø20 mm, Ø16 mm (polygon cutting) |

| I.D. tool shank | Ø25 mm |

| Spindle motor (15 min./cont.) | βiI8 (14.7 HP /10 HP) |

| Servo motor | X: βiS 8 (1.6 HP) / Z: βiS 8 (1.6 HP) |

| Hydraulic unit motor | 1 HP |

| Coolant pump motor | 1/2 HP |

| Height of machine | 2070 mm |

| Length of machine | 1800 mm |

| Width of machine | 2015 mm |

| Weight of machine | 2300 kg |

- Specifications are subject to change without notice.